So many couplings, how do you choose? How do we balance our torque requirements vs bore sizes vs material required?

February 14, 2022 / Couplings

Every other day, we get questions such as:

- What’s the difference between a set screw and clamp type coupling?

- Can I replace my coupling with a different type of coupling?

- The coupling you offered looks different from mine, are they equivalent?

- Do you have stainless steel couplings?

- The regular coupling I’m using spoils very frequently, can you suggest a better one?

- I’ve only heard about Oldham couplings. What’s the difference between Oldham couplings and other couplings?

In today’s article, we will be addressing these questions. Specifically, we will be talking about couplings that allows for bore hole sizes up to 70mm shaft. These couplings are mostly used in automation industries, so if you are in the semiconductor, automation, electronics, medical, OEM, machine making sector, this is for you.

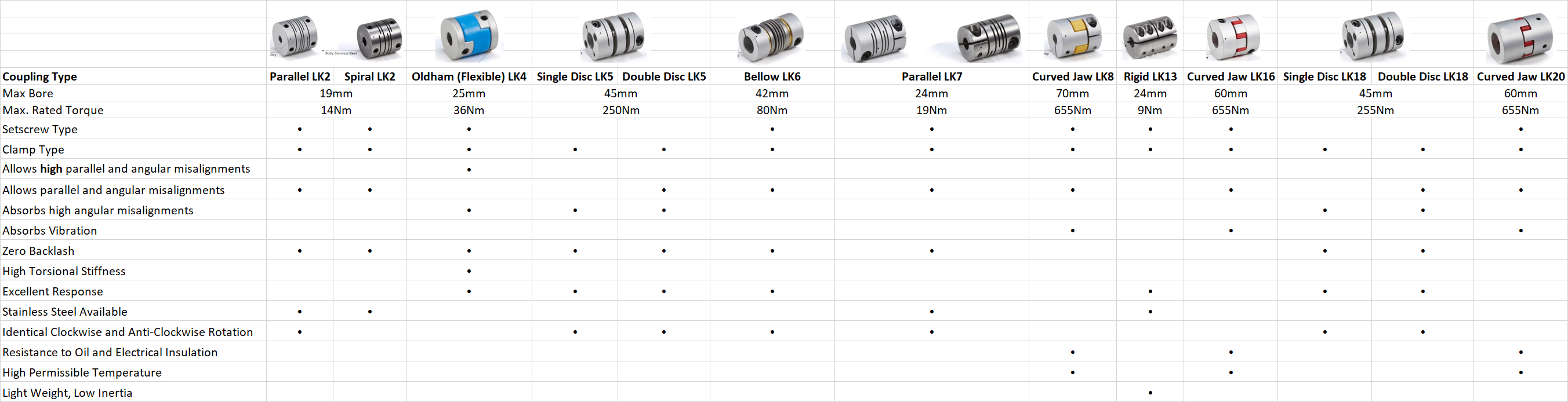

Here we present, the mother of coupling tables.

You do not have to flip through catalogues to make comparisons, because we have done the legwork for you.

Let’s do a walk-through with reference to the coupling table to answer all of above questions.

- Can I replace my coupling with a different type of coupling?Depends! Chances are, you can. For example, you are using a curved jaw coupling of shaft size 25mm, and you are looking for alternatives. Simply do these checks according to the table- Does your machine vibrate? Is your environment oily? Does it pass through electricity? Is it running under intense temperatures? If the answers to all of that are no, the comparison table shows that you may replace it with a Disc or Oldham coupling, which might be even more suitable for your application if you are experiencing larger misalignments. Of course, be sure to check the catalogues to compare the other technical features such as rotational speed, torsional stiffness etc. You can find these catalogues on our site for easy reference.

- What’s the difference between a setscrew and a clamp-type coupling?Setscrew couplings come with a recessed socket screw, which goes perpendicular to the shaft. To install a setscrew coupling, allow the coupling to slide on the shaft and at a suitable length, then tighten the screws. To achieve the best hold, the shaft material should be softer than the screw to allow the screws to dig into the shaft and resist axial loads and torsional force. Most of the time, keyways are machined into the couplings to create a better hold. Clamp-type couplings use socket head screws that are recessed into the coupling to create compressions on the shaft when the screws are tightened. This makes removal and re-installation easier when adjustments are needed, because clamp-type couplings do not dig into the shafts, resulting in less damage. Shaft material is less important in clamp-type couplings as compared to set-screw couplings, and keyways are not usually needed as the force holding the shaft’s more uniform. Depending on coupling sizes, clamping screws typically have twice as much holding power compared to setscrew couplings.

- The coupling you offered looks different from mine, are they equivalent?As seen from the table above, couplings are versatile and can take many forms. Even similar type of couplings (i.e Disc couplings, Curved Jaw couplings, Parallel couplings) come in different sizes and corresponding length! If we are offering an equivalent, it is likely because the couplings you are using is obsolete, or that we can a faster lead time equivalent or a more cost-effective solution for you! As long as the requirements meet your request, it is okay to change.

- Do you have stainless steel couplings?Yes, we do! The summary table shows the types of couplings with stainless steel options. Or you can click here and filter for ‘Stainless steel’ to search for your exact coupling. In addition, there are couplings with oil resistance, electrical insulation properties. and those that withstand extreme temperatures like below freezing and above boiling point!

- The regular coupling I’m using spoils very frequently, can I replace with yours?Couplings do not typically spoil easily, so the first factor that we have to determine if it is undersized. Is the bore hole above the recommended size (reminder to take keyway height into consideration!), and does the torque and speed ratings meet your application requirements? It is wise to take into consideration the application’s running hours, and put in safety factors when sizing your coupling. Otherwise, you may also refer table above to consider the replacement of your coupling.

- I’ve only heard about Oldham couplings. What’s the difference between Oldham couplings and other couplings?This is especially easy to see with the summary table above. While the Oldham coupling’s a very popular and reliable coupling, it does have its limitations. The bore hole’s up to 25mm, and with a lesser rated torque compared to the other couplings. Here, we would like to further elaborate on some of the terms.

- Excellent response refers to the moment of inertia at the time of application’s start and stop.

- Torsional stiffness refers to the rigidity against the torsion on the coupling

At Shafttech, we are able to take on additional machining such as Bore Holes and Keyways should you require them. Our website also offers 3D drawings for our miniature couplings range

.

We hope that this is an informative read, and always feel free to check in with us if you have further queries!