In the world of machinery and industrial equipment, the seamless transmission of power and motion is a critical factor in ensuring optimal performance. In heavy industries, disc couplings play a pivotal role in this process. It is perfect for high speeds and even high torque. Disc couplings accommodates a good degree of misalignment, and efficiently transmits torque with with utmost reliability. Among the various options available, ESCO disc couplings stand out for their exceptional engineering and the unique benefits they bring to the table. In this article, we will delve into the realm of ESCO disc couplings, exploring their different types and the valuable advantages they offer to industries.

ESCO Disc Couplings: An Overview

ESCO, a renowned manufacturer with a long history of over a 100 years, is specialised in the manufacturing of couplings. They are globally recognised for their gear and disc couplings that cater to the diverse needs of industries. ESCO couplings originate in Belgium and are celebrated for their precision engineering, resilience, and ability to accommodate substantial misalignment. ESCO Couplings is a manufacturer which focuses their core business on the design and manufacture of great couplings which makes ESCO coupling the preferred choice across various applications.

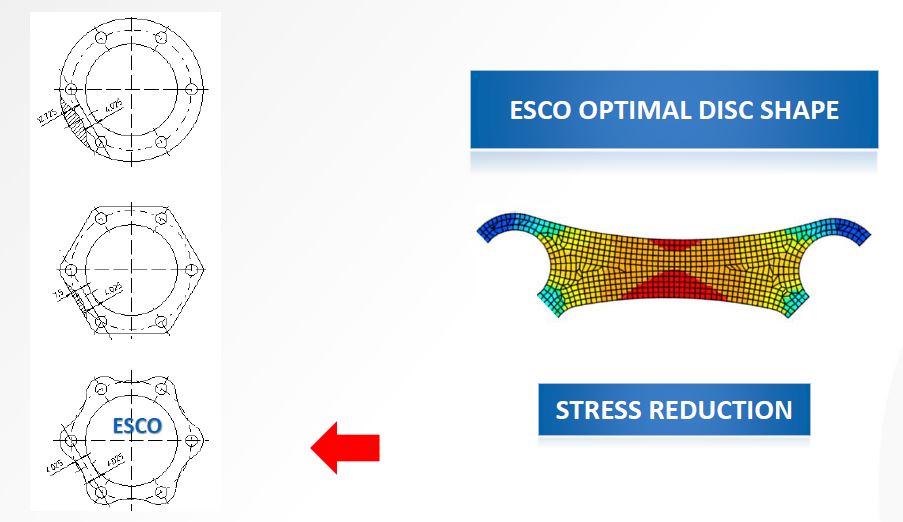

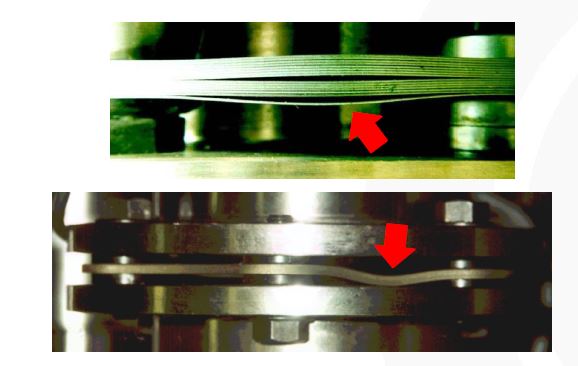

ESCO Disc Couplings – Why they stand out?

ESCO disc couplings bring several significant advantages to the table, making them the preferred choice for numerous industries:

Types of ESCO Disc Couplings:

ESCO Disc Couplings are used across many industries including: Agriculture, Cement, Food and Beverage, General Machines, Petrochemical and Refinery, Power Generation, Quarrying and Mining, Rail, Renewable Energy, Steel & Non-Ferrous, Textile, Wood Pulp and Paper

ESCO offers a range of disc coupling types, each tailored to specific industrial requirements:

3. ATEX Disc Couplings

ESCO disc couplings represent a pinnacle of innovation and engineering excellence. Their ability to tolerate misalignment, transmit high torque, and ensure long service life has made them indispensable across various industries.

Shafttech can assist with the selection of couplings for your specific applications, ultimately enhancing your equipment’s performance and longevity. For strive to service with short lead times, and partner our clients on custom designs.Send us your enquiry at sales@shafttech.com and we will be able to select a suitable coupling for you.