Tyre couplings play a crucial role in connecting rotating shafts and transmitting power efficiently. Whether you are replacing existing couplings, choosing tyre couplings for new projects, or exploring new options, choosing the right tyre coupling is essential for maintaining optimal performance and preventing downtime. In this guide, we’ll explore two perspectives on selecting the right tyre coupling: one for replacement and the other for a brand new selection.

Replacing your Couplings: Ensuring Compatibility for Efficient Replacement

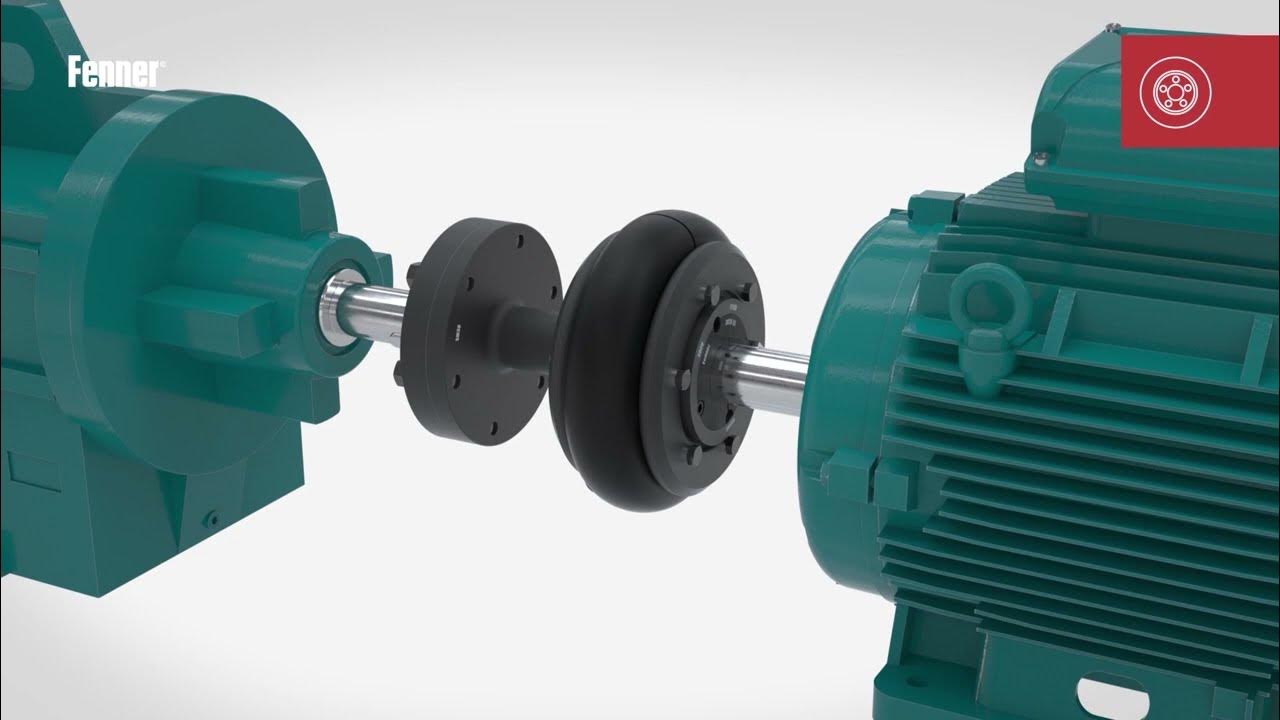

When replacing a tyre coupling, it is crucial to identify and match the specific model and components. The tyre coupling consists of five main parts: the tyre, the two hubs, and the two taper bushes. Here’s a step-by-step guide to selecting the correct replacement parts:

a. Identification of part number on Tyre couplings and Taper Bush: Start by examining the existing tyre. Look for any markings, model numbers, or specifications imprinted on the surface. These markings often include information about the material, size, and load capacity of the tyre. Take note of these details as they are crucial for finding a suitable replacement.

Image 1: The part number “F110H-3020” is printed on the hub. This is the full Tyre coupling part number. “3020” stands for the taper bush part number.

Note that if there’s special indications such as FRAS, which stands for “Fire Resistant Anti Static”.

b. Consult with Experts: If you encounter challenges in identifying the coupling model or finding suitable replacement parts, let Shafttech know and we will assist with this.

New Selection: Selecting Tyre couplings for new applications or projects or Changing a Pin & Bush Coupling to Tyre Coupling

Selecting a tyre coupling from a catalogue involves a systematic consideration of various parameters to ensure compatibility with your specific application. Here’s a step-by-step guide that takes into account motor power, output speed, output torque, shaft sizes, and DBSE (Distance Between Shaft Ends):

By following these steps and considering motor power, output speed, output torque, shaft sizes, and DBSE, you can make a comprehensive and informed selection of a tyre coupling that meets the specific needs of your application. Shafttech is an expert in couplings for all industries. If you are looking for any kind of couplings, contact us today at sales@shafttech.com and we will be able to discuss your specific needs.