Tyre couplings play a vital role in power transmission systems, providing flexibility, vibration damping, and misalignment compensation. However, like any mechanical component, tyre couplings can experience issues that may affect their performance. Troubleshooting common problems promptly is crucial to ensure optimal operation and prevent potential equipment failures. In this article, we will discuss some common issues that may arise with tyre couplings and provide troubleshooting steps to help you identify and resolve them effectively.

1. Excessive Vibration: Excessive vibration is a common problem that can lead to increased wear, misalignment, and potential equipment damage. If you notice excessive vibration in your machinery, follow these troubleshooting steps:

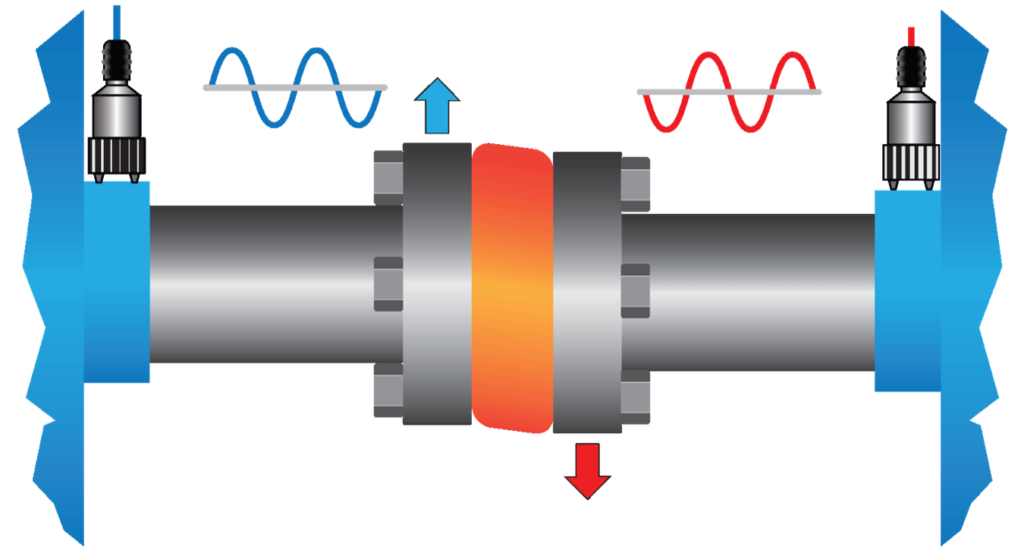

a) Check for proper alignment: Misalignment between the driving and driven shafts can cause increased vibration. Verify that the shafts are aligned correctly according to the manufacturer’s specifications.

b) Inspect for damaged or worn-out tyres: Over time, the rubber tyres of the coupling can deteriorate or develop cracks. Inspect the tyres for any signs of damage or wear and replace them if necessary.

c) Verify proper installation: Ensure that the tyre coupling is installed correctly, with all bolts tightened to the recommended torque. Loose or improperly installed couplings can cause excessive vibration. Watch this video to see how simple it is to install a Fenaflex™ tyre coupling.

2. Misalignment Issues: Misalignment can occur due to various factors, including improper installation or wear over time. If you suspect misalignment, follow these troubleshooting steps:

a) Check alignment: Use precision alignment tools to assess the alignment between the driving and driven shafts. Make adjustments as necessary to achieve proper alignment within the manufacturer’s specifications.

b) Inspect for worn or damaged components: Misalignment can lead to accelerated wear on the coupling components. Inspect the coupling elements, such as the tyres and hubs, for signs of damage or wear. Replace any worn-out components. You can purchase just the worn out components with Shafttech, which would translate to cost savings for you.

3. Coupling Failure or Breakage: Although tyre couplings are designed to withstand heavy loads and compensate for misalignments, they can experience failures or breakages under certain circumstances. If you encounter coupling failure, follow these troubleshooting steps:

a) Assess load conditions: Evaluate the torque and load requirements of your machinery. If the coupling is subjected to loads beyond its capacity, it can result in failure. Consider upgrading to a higher-rated coupling if necessary.

b) Check for worn or damaged components: Inspect the coupling elements for signs of wear, cracking, or damage. Pay attention to the tyres, hubs, and bolts. Replace any damaged components to prevent coupling failure.

c) Preventive Maintenance: Establish a maintenance routine: Regularly inspect the coupling for signs of wear, misalignment, or damage. Schedule routine maintenance tasks such as visual inspections, bolt torque checks, and tyre condition assessments. Address any identified issues promptly.

Troubleshooting common issues with tyre couplings is essential for maintaining efficient and reliable power transmission systems. By promptly addressing excessive vibration, misalignment, coupling failure, and ensuring proper lubrication and maintenance, you can prolong the lifespan of the couplings and prevent unexpected equipment failures. If you encounter complex or persistent issues, do consult us at Shafttech as we have experienced professionals who can assist you in accurate troubleshooting and resolution. If you are looking to change to a tyre coupling, check out this article for the amazing benefits of a Fenner tyre coupling.