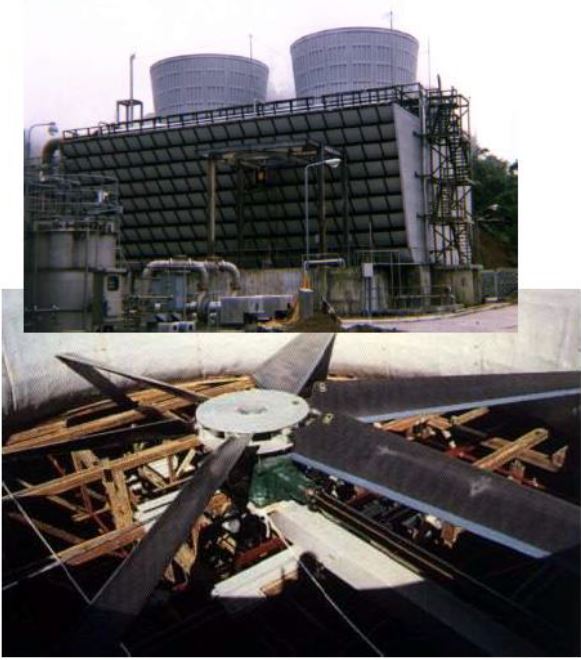

Among the vital components of a cooling tower, couplings play a crucial role. Couplings connect the motor and the gearbox to the cooling tower fan, ensuring smooth and efficient power transmission. They must withstand harsh operating conditions, including high torque, misalignment, and thermal expansion. High-quality couplings reduce maintenance costs, improve efficiency, and extend the lifespan of the cooling tower.

One of the standout solutions in the cooling tower coupling market is the ESCO FIL (Composite) Coupling. Recently, in a significant oleochemical plant cooling tower in Malaysia, the ESCO FIL Coupling E75 S3 was proposed to replace traditional elastomeric couplings, which needed to be changed every 3-6 months. This replacement was driven by the need for a more robust and reliable solution.

1.Weight: The composite material of ESCO FIL Couplings makes them lighter than traditional elastomeric couplings, reducing the load on the cooling tower’s drive system.

2.Long distance between shaft ends (DBSE): ESCO FIL Couplings enable long DBSE without the need for support bearings, unlike elastomeric couplings.

3.Lifespan: ESCO FIL Couplings offer a longer lifespan due to their superior resistance to wear and environmental factors, leading to fewer replacements and lower maintenance costs. Specifically designed for cooling tower applications, these couplings are corrosion-resistant and can last up to 10 years with minimal maintenance.

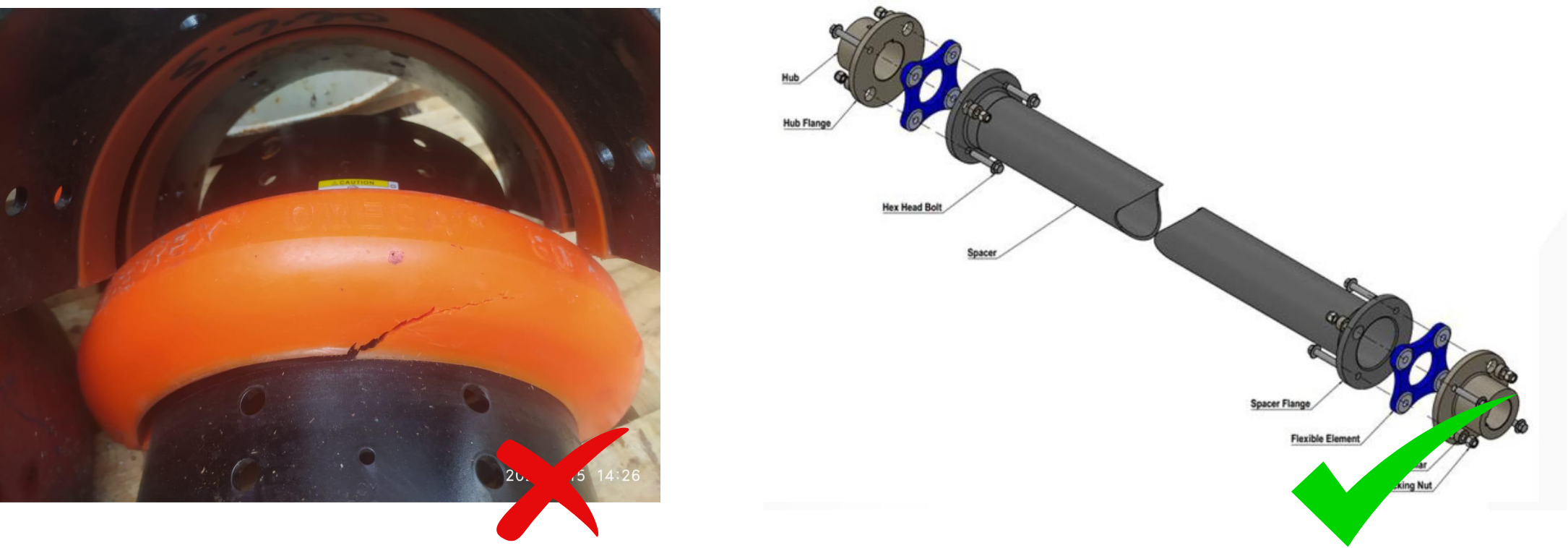

4.Maintenance: ESCO FIL Couplings require little to no maintenance, unlike the elastomeric couplings which typically requires a change in element every 3-6 months. We do recommend a visual inspection on the disc element during regular equipment maintenance. If damaged by unforeseen external factors such as increased loading or massive shaft alignment, the disc elements can be replaced easily as well.

5.Cost: Despite their advanced features, ESCO FIL Couplings are cost-effective in the long run due to their durability and reduced need for frequent maintenance. The initial investment in these couplings is offset by the savings in maintenance and downtime costs.

6. Material: Plants like oleochemical often present a harsh corrosive environment for their equipment with water, chlorine and bromine. The hubs and hardware are made from stainless steel for added corrosion protection in aggressive environments. The hubs and hardware are made from stainless steel for added corrosion protection in aggressive environments.

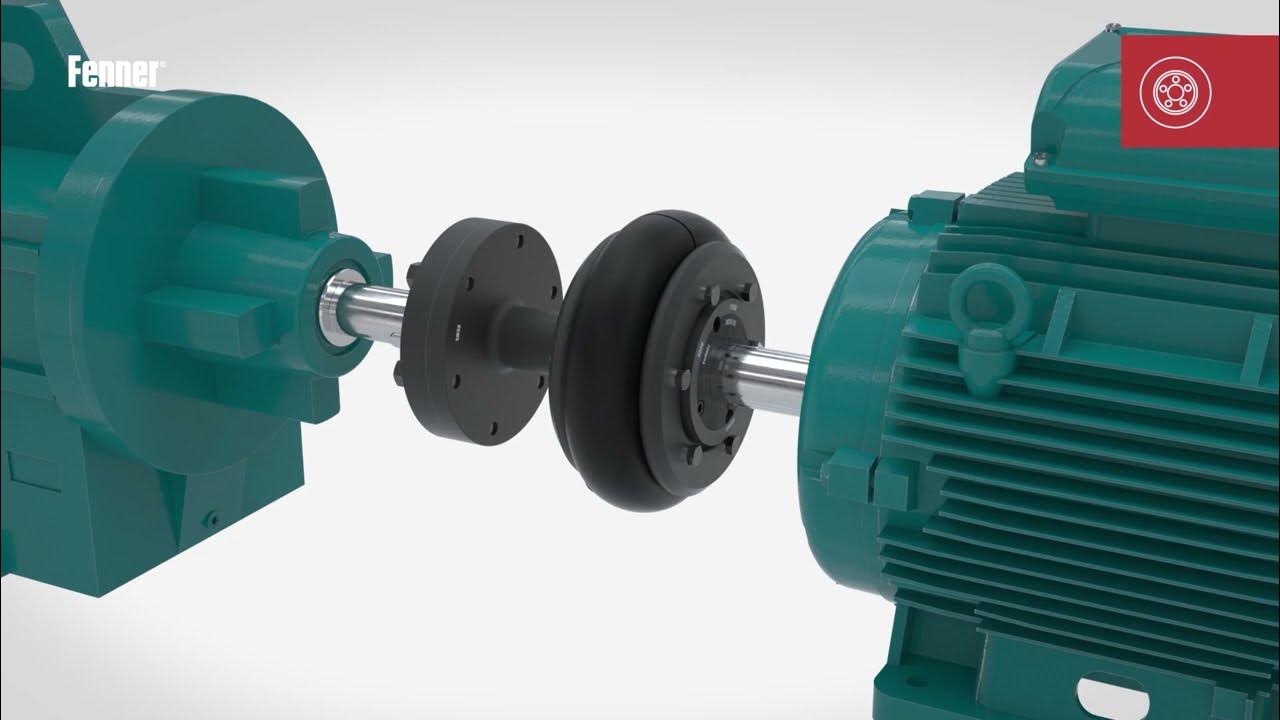

While ESCO FIL Couplings are perfect for large, demanding applications, tyre couplings, such as Fenner Spacer-type Tyre Couplings, are suitable for smaller cooling towers. These couplings offer flexibility and ease of installation, making them ideal for less demanding applications. They can absorb misalignment and vibrations, protecting the connected equipment from potential damage.

Perfect for Long DBSE: Spacer-type Tyre couplings from Fenner, known as the Fenaflex Spacer, consists of an additional spacer flange assembly. Designed for standard DBSE 80, 100, 140 and 180mm, perfect for cooling towers!

Misalignment Capacity: Fenner Tyre Couplings are designed to handle high amounts of misalignment and dampen vibrations, ensuring smooth operation of the cooling tower.

Ease of Installation: These couplings only require a replacement of the tyres without shifting machinery, making them easy to install and maintain. Spacer-tyre tyre couplings also only required to move both shaft axially without disturbing the drive nor driven machine (e.g. centrifugal pump rotors). Therefore, reducing the time and effort required for setup and replacement.

Cost-Effective: Fenner Tyre Couplings provide a cost-effective solution for smaller cooling towers, balancing performance and affordability.

Choosing the right coupling for your cooling tower is critical for ensuring operational efficiency and longevity. Whether you need the robust performance of ESCO FIL (Composite) Couplings for large industrial cooling towers or the flexibility of Fenner Tyre Couplings for smaller setups, Shafttech provides the expertise and high-quality products to meet your needs.

Contact us today to learn more about our coupling solutions and how we can help you enhance your cooling tower performance.

Visit here for more information.