The oil and gas industry relies on complex machinery and equipment, including ATEX (Atmosphères Explosibles) couplings, to operate safely and efficiently in potentially explosive environments. In this article, we will provide a comprehensive review of ATEX couplings from renowned brands like ESCO, Renold, Fenner, and Rexnord Thomas.

Understanding ATEX Couplings

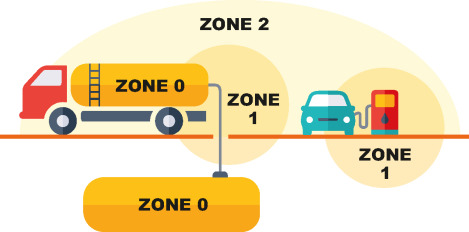

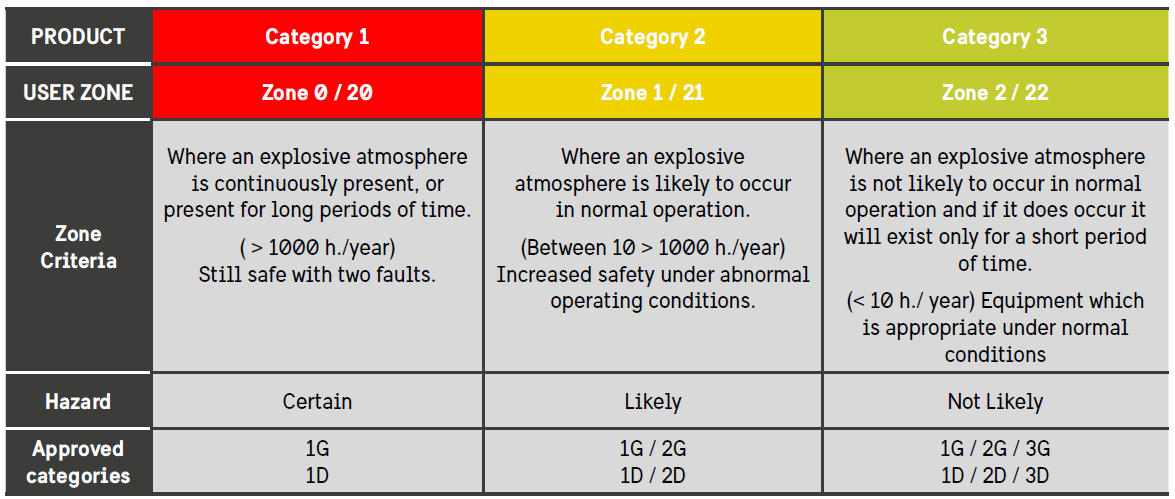

ATEX couplings are crucial for operating in environments with explosive gases, vapors, or dust. They adhere to the ATEX directive, setting standards for equipment and protective systems used in explosive atmospheres. ATEX couplings are primarily used in Group II environments, which encompass various industries, including oil and gas.

Shafttech is the the official distributor for ESCO, Renold and Fenner ATEX couplings.

Each of these brands carry different types of ATEX couplings. In this article, we will highlight their advantages and usage in the Oil & Gas industry.

ESCO ATEX Disc Couplings: Ensuring Safety and Reliability

ESCO is a global leader in ATEX Disc couplings for the oil and gas industry. ESCO’s ATEX Disc couplings are engineered with precision and robustness, ensuring safety and reliability in hazardous areas. With top-notch materials and advanced engineering, ESCO’s products are a trusted choice for professionals in the industry. Shafttech has been appointed the official distributor of ESCO Couplings.

ESCO’s Disc Couplings are designed, calculated and tested for infinite life. These couplings allow for high torque and misalignment capacity, has excellent inherent balance and is easy to assemble and disassemble. For maintenance, it is easy as no lubrication is required and inspection of coupling can be done without disassembling it. For more in depth information on ESCO Disc couplings, you can find it here.

ESCO ATEX Disc couplings is an add-on option for use in explosive environments. This ESCO ATEX variant has “EX” markings on the coupling as seen in the image above. This signifies to the engineers that it is an ATEX-certified coupling. For ESCO Disc couplings, Shafttech’s engineers will do their selection based on ESCO DPU Series, which meets API610 Standards (American Petroleum Institute).

Renold ATEX Flexible Couplings: Innovation and Quality

Renold, a reputable name in power transmission solutions, offers a range of ATEX couplings tailored for the oil and gas market. Renold’s ATEX couplings are known for their longevity, performance, and commitment to innovation and quality. They are a preferred choice for reliable solutions in hazardous areas.

As Renold’s official distributor, Shafttech has served many companies in the oil and gas sector. Common series of Renold couplings include the Renold DCB-GS Flexible Coupling, the Renold RB Flexible Coupling, and Renold HTB-GS Flexible Coupling. Shafttech can provide both the replacement parts like the rubber blocks and rubber tubes, or the whole set coupling.

Fenner ATEX Tyre Couplings: Durability and Adaptability

Fenner is known for its ATEX coupling solutions that meet the stringent safety and performance requirements of the oil and gas sector. Fenner’s ATEX couplings are designed for durability and adaptability, making them valuable in oil and gas operations where safety is paramount. Tyre couplings are known to take high amounts of misalignment and dampen shock vibrations from surrounding equipment. It is also one of the easiest coupling to maintain as you only need to replace the tyre element once every 2-3 years. The fact that they can be used in almost all applications make them one of the most popular couplings in the market now. More information on Fenner Tyre couplings here.

Shafttech also distributes Fenner Tyre Couplings with ATEX markings! These are typically used with the FRAS (Fire Resistant Anti Static) tyres in the oil and gas sector. Should you require ATEX certifications or markings on your tyre couplings, please enquire with us.

Rexnord Thomas ATEX Couplings: Safety and Reliability

Rexnord Thomas is another trusted provider of ATEX couplings in the oil and gas industry. Rexnord Thomas ATEX couplings prioritize safety and reliability, performing well in challenging conditions and offering superior protection against the hazards of explosive atmospheres.

Shafttech is well-versed in selection of ATEX couplings, which can often be quite tricky to do. We have worked with numerous Chemical, Oil & Gas plants in replacing their non-ATEX couplings to ATEX ones to ensure safety compliance. Our technical engineers will conduct a site visit for a full technical assessment before selecting a suitable coupling for the application.

Send us your enquiry at sales@shafttech.com and we will be able to select a suitable coupling for you.