When it comes to power transmission systems, selecting the right coupling is crucial for ensuring efficient and reliable machinery operation. Tyre couplings, otherwise known as tire couplings, offer unique advantages in compensating for misalignments, dampening vibrations, and transmitting torque. However, choosing the right tyre coupling requires careful consideration of various design factors. In this article, we will explore the key design considerations, including misalignment compensation capability, torque transmission capacity, size and space constraints, environmental factors, maintenance and inspection requirements, and cost and long-term value.

1. Misalignment Compensation Capability:

One of the primary functions of a tyre coupling is to compensate for misalignments between the driving and driven shafts. When evaluating tyre couplings, consider their ability to handle angular, parallel, and axial misalignments. Tyre couplings have a large misalignment capability. the Fenner’s Fenaflex Tyre Coupling can take up to 4° angular and 6mm parallel and 8mm axial misalignments. Look for flexible elements with sufficient torsional stiffness to absorb misalignments while maintaining the required torque transmission capacity. Proper misalignment compensation minimizes stress on connected machinery, reduces wear and tear, and extends the operational life of your equipment.

2. Torque Transmission Capacity:

Evaluate the torque requirements of your machinery and ensure that the selected tyre coupling can handle the expected torque load. Consider factors such as the power requirements, start-up torque, and any intermittent or peak torque conditions. Ensure that the coupling’s torque rating matches or exceeds your machinery’s requirements to ensure reliable and efficient power transmission. Fenner’s Fenaflex Tyre Coupling has a selection of torque capacity up to 12606Nm and bore diameters up to 190mm.

3. Size and Space Constraints:

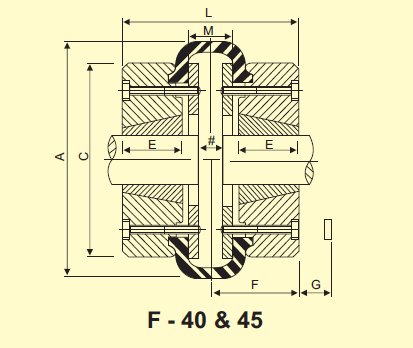

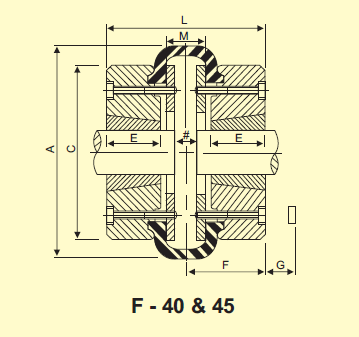

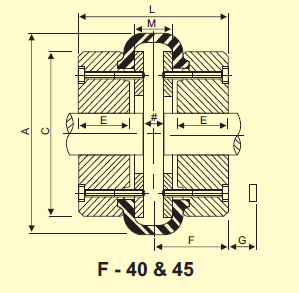

Examine the available space for the coupling installation. Tyre couplings come in various sizes and configurations. Ensure that the selected coupling can be accommodated within the available space without interfering with other components or creating installation challenges. Consider factors such as the coupling’s overall dimensions, flange sizes, and shaft bore sizes to ensure a proper fit within your machinery. In general, the flanges are available in either F and H configurations for taper-lock fitting, or B configuraiton for pilot bore flanges. F configuration is where the taper lock bush is fitted from inside of the coupling, whereas H is from the outside. Depending on the space constraints, there can be different combinations such as F/F, F/H, F/B, H/B.

Image 1: [Left] F/F type configuration. [Middle] H/H type configuration. [Right] B/B tye configuration.

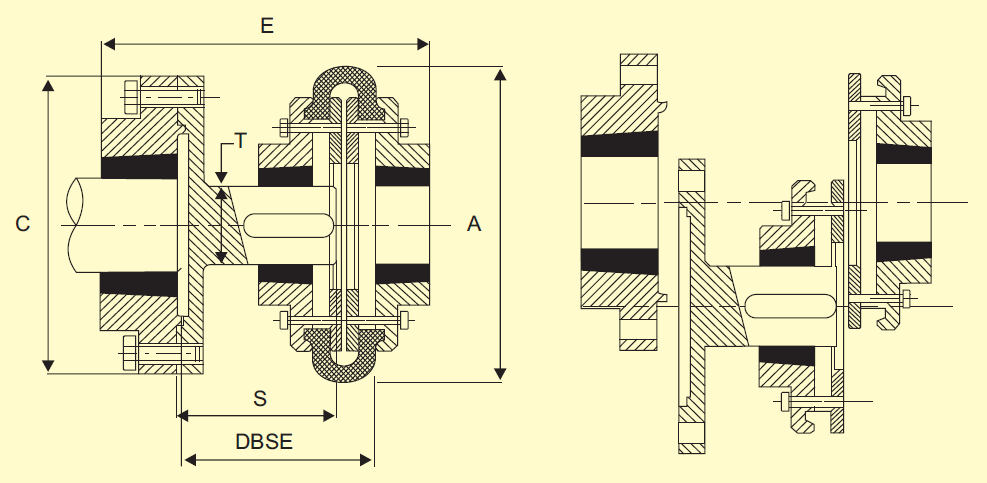

Fenner offers spacer type tyre couplings that are specifically designed for applications with larger space required between the drive (motor) and driven (application). These spacer couplings provide an extended distance between shaft ends, allowing for more flexibility in installation. At Shafttech, we keep stock for Fenner spacer type tyre couplings, ensuring quick availability and delivery for your specific space requirements. By choosing a spacer type coupling, you can optimize the use of available space and ensure a proper fit within your machinery.

Image 2: Illustration of Fenner spacer type tyre coupling.

1. Environmental Factors:

Assess the environmental conditions in which the machinery will operate. Consider factors such as temperature variations, exposure to moisture or chemicals, and potential contaminants. Choose a tyre coupling that is designed to withstand the specific environmental conditions of your application. This may include selecting couplings with protective coatings, corrosion-resistant materials, or enhanced sealing mechanisms for optimal performance and longevity.

In certain applications, such as those with a risk of fire or the presence of static electricity, Fenner Brand Tyre Couplings offer Fire Resistant Anti Static (FRAS) options. These FRAS couplings provide an extra layer of protection against fire hazards and static electricity. At Shafttech, we maintain stock of Fenner FRAS tyre couplings, enabling you to meet your environmental requirements promptly and efficiently.

2. Maintenance and Inspection Requirements:

Consider the maintenance and inspection requirements of the selected tyre coupling. Some couplings may require periodic lubrication, while others may offer maintenance-free operation. You can check out Fenner’s Fenaflex Tyre Coupling as it is lubrication-free. Additionally, consider the ease of inspection and the availability of spare parts when evaluating different tyre coupling options.

3. Cost and Long-Term Value:

Evaluate the initial cost of the tyre coupling, but also consider its long-term value. A higher-quality coupling may have a higher upfront cost but can provide significant cost savings in terms of reduced maintenance, longer service life, and improved machinery performance. For example, a pin and bush coupling may be economical, but the lifespan is considerably shorter and requires replacement of the entire coupling. Whereas for a tyre coupling, you only need to replace the tyre of the coupling while the flanges can last more than 10 years with proper maintenance. This makes tyre coupling more desirable in most cases. It is essential to strike a balance between the initial investment and the long-term benefits to achieve the best value for your machinery. Watch this video on how simple it is to install a Fenaflex™ tyre coupling.

Selecting the right tyre coupling for your machinery involves careful consideration of design factors such as misalignment compensation capability, torque transmission capacity, size and space constraints, environmental factors, maintenance and inspection requirements, and cost and long-term value. By thoroughly evaluating these design considerations and taking advantage of Fenner’s spacer type tyre couplings for space constraints and Fire Resistant Anti Static (FRAS) options for challenging environmental conditions, you can ensure the optimal performance, reliability, and longevity of your machinery’s power transmission system.

Feel free to consult Shafttech to find the perfect tyre coupling that meets the specific requirements of your application. We are official partner for Fenner (UK). With our stock availability and expertise, we can assist you in making the right choice and ensuring the reliable and efficient operation of your machinery.

If you want to learn more about the types of coupling to use, watch this video where we invited an expert from Fenner to discuss how to select the right kind of coupling for different applications.