Chemical plants are the lifeblood of many industries, producing everything from fertilizers and plastics to pharmaceuticals and cleaning agents. But behind the complex chemical reactions lies a hidden world of essential mechanical products. These workhorses, both the well-known and the less-celebrated, keep the processes running smoothly, efficiently, and most importantly, safely.

The Flow of Power: Pumps, Compressors, and their Transmission Partners

At the heart of material movement are pumps, the tireless champions of liquid and slurry transfer. But a pump’s success story relies on its supporting cast:

Couplings

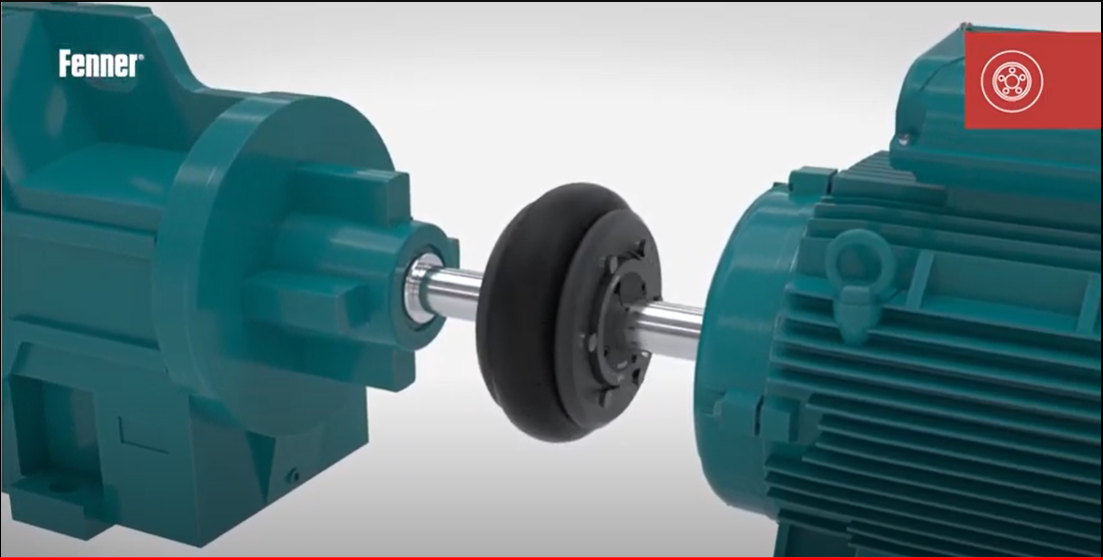

The critical link between the pump shaft and the motor’s driveshaft.

1.Gear couplings ensure smooth power transfer for applications with perfect shaft alignment. ESCO Gear Couplings are known in the market for its ability to transmit high torque despite a small coupling size, reducing stress on on machinery.

2.Tyre couplings or Disc Couplings are often used to accommodate shaft misalignment while dampening vibrations. Fenner Tyre coupling is the market standard for tyre couplings; Installation is easy and you only require to change tyres every 1-2 years, which makes it perfect for most pumps. If the torque capacity and speed is higher, ESCO Disc Couplings will come in handy. ESCO Disc couplings are designed for infinite life, and no lubrication is needed. For chemical plants, ATEX certification is sometimes required, and ESCO Disc couplings can offer an ATEX disc couplings for hazardous environments. When high shock loads are anticipated, jaw couplings with their interlocking teeth provide a robust connection.

Gearboxes

When a pump requires a change in speed or torque output from the motor, gearboxes step in. These marvels utilize a series of precisely machined gears to achieve the desired speed or torque multiplication, allowing the pump to operate at its optimal efficiency. Helical gearboxes offer smooth, quiet operation, while helical-bevel gearboxes provide a right-angle power transfer with high efficiency. The Fenner (UK) Bevel Helical gearbox is popular for chemical plants due to its high quality and cost-effectiveness.

The Art of Mixing: Mixers, Agitators, and their Unsung Heroes

Many chemical reactions rely on constant, thorough mixing to guarantee proper ingredient interaction. Mixers and agitators come in various forms, but their operation hinges on:

Shafts

These long, rotating rods act as the power conduit, transmitting torque from the motor or gearbox to the mixing impellers. Stainless steel shafts are a popular choice for their corrosion resistance in many chemical applications. For especially harsh environments, exotic metal alloys may be necessary.

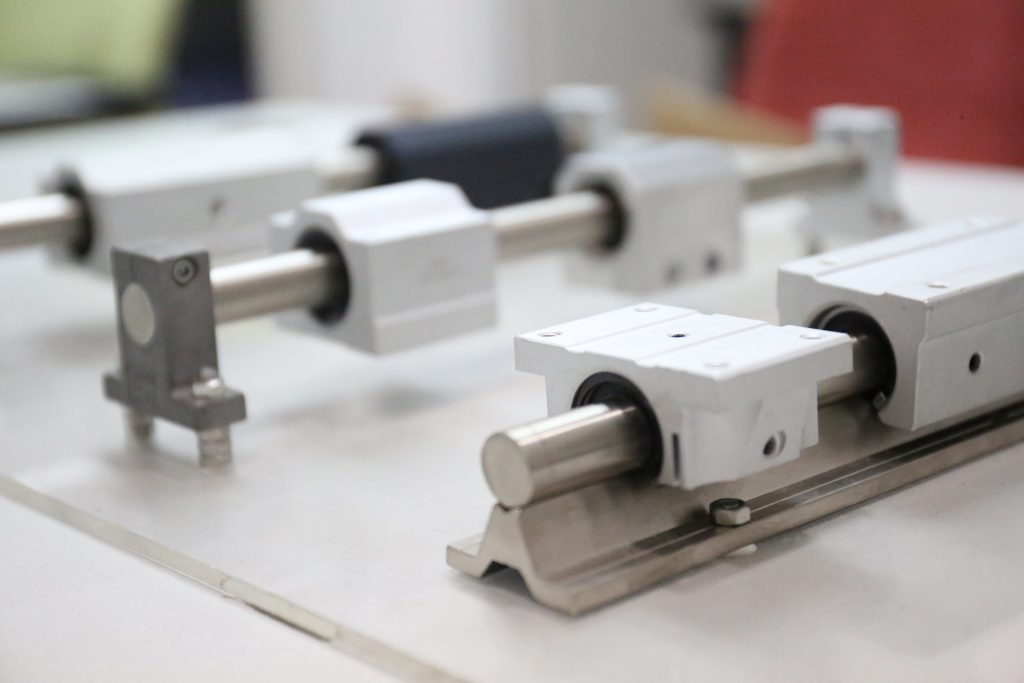

Bearings

These unsung heroes support the rotating shaft, minimizing friction and wear. Chemical plants often rely on heavy-duty bearings designed to handle high loads and withstand the corrosive nature of the processed chemicals. Self-lubricating bearings and Oilless Bushings, can be crucial in applications where external lubrication is impractical. One big exporter of Oilless Bushings is Shafttech. Shafttech carries a wide range of Oilless Bushings.

Separation Science: Centrifuges, Filters, and their Control Network

Chemical processes frequently involve separating components with distinct physical properties. Centrifuges and filters play a vital role in this separation, but they often require additional components for precise control:

Clutches and brakes

These engage and disengage power to the centrifuge or filter, enabling smooth start-up, controlled operation, and safe stopping. Magnetic particle clutches provide a non-contact, wear-free solution for high-speed applications, while pneumatic clutches offer a simple and reliable option for lower-speed requirements. Disc brakes deliver precise stopping power for a controlled deceleration of the centrifuge or filter.

Speed reducers

In some centrifuges, meticulous control over rotational speed is paramount. Planetary gear reducers or Planetary Gearboxes provide a compact and high-ratio speed reduction solution, while worm gearboxes offer a self-locking feature for applications requiring shaft hold during downtime. SITI (Italy) is a champion in this range of products, specialising in high quality worm gearboxes and and the bigger planetary gearboxes for chemical plants.

These are some of essential mechanical products that keep chemical plants running. From the powerful pumps to the precisely designed valves and their supporting cast, each piece plays a vital role in the safe and efficient production of the chemicals that underpin our modern world.

If you encounter any technical failures or wish to upgrade any part of your plant, you can contact our team of technical engineers salesco1@shafttech.com who can assist you with replacement, selection and recommendation of new parts, frequent failure inspection, cost-down maintenance. Shafttech is one of the most trusted providers for heavy industries in Southeast Asia.