What is Stainless Steel?

Stainless steel is widely favoured across industries for anti-corrosion properties. So how does stainless steel prevent itself from rusting and acid corrosion? This is due to the high concentration of chromium and nickel content present in them. Most stainless steel alloys contain at least 18% chromium. When chromium is exposed to water and oxygen, it forms a passive or inert layer of chromium oxide on the surface of the metal, which is seen as a glossy texture from the outside. The higher the chromium content, the greater protection from corrosion.

Machineability of Stainless Steel

However, there are some disadvantages to using stainless steel. Due to the high chromium content, stainless steel cannot be hardened by heat treatment. This makes it less machinable in many industrial applications, as they require greater power and strength to work on the material. It is also harder to achieve a fine surface finishing. On top of that, the density of stainless steel is higher than that of carbon steel, which means it is heavier and more difficult to handle in the manufacturing process.

Is Electroless Nickel Plating the new Stainless Steel?

Due to these reasons, engineers are actually switching to using Electroless Nickel (EN) plated steel as a substitute. EN plating is a process of administering a nickel phosphorus coating on the surface of steel by chemical reduction. EN-plated steel not only prevents corrosion, it offers excellent protection against wear and tear, therefore extending service life.

Cost is also a major factor. Stainless steel products are known to be highly expensive, costing approximately 3-5 times more than the carbon steel. EN-plated steel is a lower cost option, with prices only about 1.5 to 2 times higher than carbon steel on average. Imagine how much cost savings an original equipment manufacturer can have in just one year.

Salt Spray Study:

Some studies have also shown that EN plating offers better anti-corrosion than stainless steel. One of them is a salt spray study done by a Firearms Manufacturer. They compared EN-plated (bottom barrel in image below) and stainless steel (bottom barrel in image below) guns and bolts. The EN-plated gun outperformed the stainless steel gun significantly in terms of anti-rusting and firing performance after a 45-hr sustained exposure to salt spray.

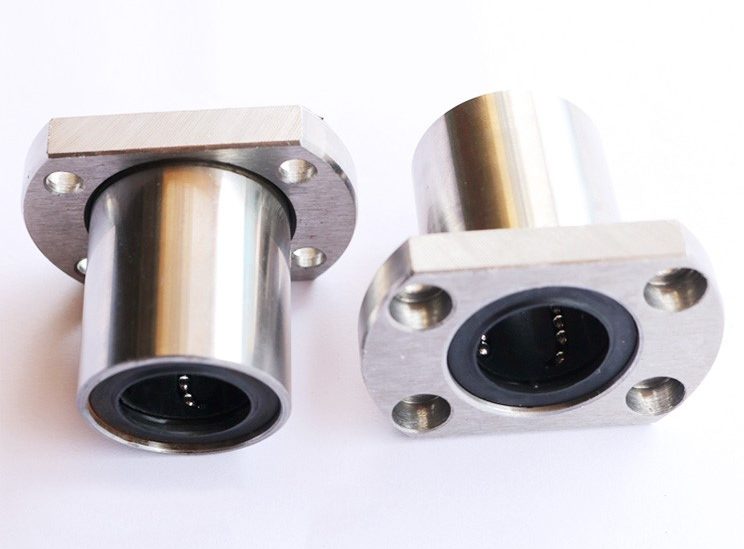

SNB Linear bearings “M” Series

Now it is no wonder that manufacturers are opting for EN-plated products instead. One of the most commonly used steel products in the market is linear motion bearings. For precision linear motion applications, linear components are often incredibly sensitive towards corrosive exposure. As manufacturers of linear bearings gradually move towards using EN plating, equipment makers and end users are now using EN-plated linear bearings as a standard for any applications that used to require stainless steel linear bearings. One of the most successful brands that offers high quality linear bearings with EN coating is SNB. SNB is a recognised brand from Singapore that specialises in linear motion components. Their linear bearing “M” series offers excellent corrosion resistance and high durability. They are now sold worldwide in over 10 countries.

Having said that, stainless steel is still highly popular in our day-to-day products and still offers excellent rust protection and strength. While EN Plating cannot completely replace stainless steel, it has shown to be a cost-effective and durable alternative for industrial solutions.