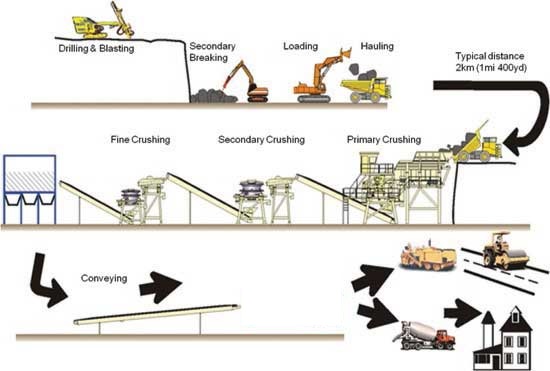

Quarries are the industrial giants that provide the raw materials for construction, infrastructure, and countless other applications. But these massive operations rely on a complex network of machinery, and within that machinery lies a world of essential mechanical parts working tirelessly. Let’s delve into some of the key equipment found in a quarry and the mechanical parts that keep them functioning.

1. Drilling and Blasting:

Drill Rigs: Powerful rotary or hammer drills use high-strength drill bits and robust bearings to penetrate rock. Hydraulic cylinders power the drill’s movement, while valves control fluid flow. Here, different types of couplings come into play:

-Rigid flanged couplings: These couplings connect the drive shaft from the engine or motor to the gearbox of the drill.

-Power Locks: Heavy duty shaft locking devices are also used on rigid flanged couplings. They provide easy, strong, and secure connections between shafts and hubs without backlash.

-Jaw couplings: Fenner Jaw couplings are perfect for absorbing shock and misalignment between the engine and gearbox, protecting the drivetrain.

2. Excavation and Loading:

Excavators: These versatile machines feature a hydraulic arm with a powerful bucket attached. The arm’s movement is controlled by a network of hydraulic pumps, motors, and valves. Tracks or wheels provide traction, while slewing rings allow the excavator to rotate its upper body. The excavator’s performance relies heavily on:

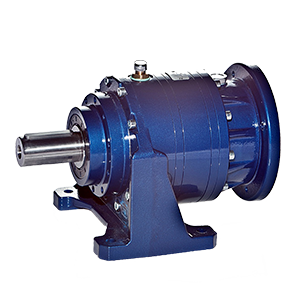

-Gearboxes: Excavators require gearboxes to increase the torque from the hydraulic motors to provide the necessary digging force at the bucket. These heavy-duty operations often use a planetary gearbox. Check out the SITI Planetary gearbox – used commonly in quarries, this gearbox is compact, and has a high power density with high efficiency continuous operation.

-V-belts: These are often used to drive auxiliary systems on the excavator, like the cooling fans. Check out Fenner V belts as they used commonly in quarries and one of longest-lasting belts out there.

3. Crushing and Screening:

Jaw and cone crushers: Jaw crushers use massive jaws with replaceable wear plates and leverage shafts, bearings, and eccentric mechanisms to break down rocks. Cone crushers, on the other hand, rely on a spinning cone and a fixed wall, using conical bearings and shafts for size reduction. Motors drive the cone’s rotation, and similar to jaw crushers, they likely utilize couplings and gearboxes to achieve the perfect crushing speed and force. Both crusher types then use screens to sort the crushed material into desired sizes.

-Couplings: Similar to drill rigs, jaw crushers likely use flange or jaw couplings to connect the motor to the crusher’s main shaft.

-Gearboxes: Gearboxes are crucial in jaw crushers, as they step up the motor’s speed and torque to create the immense crushing forces.

-Crusher Jamming: Crusher jamming incidents are a frequent headache in quarries, caused by things like big rocks, stray metal, or even wet material. These jams can quickly ruin the crusher’s belts by overheating and burning them. To keep downtime to a minimum during these emergencies, it’s important to have the right replacement belts on hand and ready to swap in. In this case, the Fenner PowerTwist Plus belt is a problem-solver and a game-changer. They are built to replace those old metric SPZ, SPA, SPB and SPC wedge belts, and they work perfectly on existing pulleys. One huge advantage is that these “link belts” work like a chain- you can add or remove links during installation and adjust to get the exact length you need for your machine. they also conquer tough environments with oil, grease, water, most chemicals and solvents. They resist abrasion better and can handle a wider temperature range, from a frigid -40°C to a scorching 116°C.

4. Conveying Systems:

Belt Conveyors: Belt conveyors are the most prevalent type of conveyor system employed within the mining and quarrying industries.

-Gearboxes: These conveyors, sometimes referred to as feeders, utilize shaft-mounted gearboxes to facilitate material transportation along inclines of minimal grade. The Fenner SMSR Gearbox (shaft mounted speed reducer) is used commonly in this application, with torque capacity up to 45,000Nm. It consists of a taper-Grip bush for easy removal and fitting. Additionally, bevel helical and worm gear reducers find application in these belt conveyor systems. Shafttech has assisted many quarries in using SITI bevel helical and SITI worm gearboxes (Italy) for high quality and reliable operations.

-Idlers and rollers: These support the conveyor belt and ensure smooth movement of the material.

-Scraper blades: These remove excess material buildup on the belt to prevent slippage and belt damage

Ensuring your quarry runs smoothly requires reliable and efficient equipment. Our team of experts can assist you in selecting the right compressors, crushers, conveyors, and other essential equipment to maximize productivity and minimize downtime.

Contact Shafttech today and let us be your partner in achieving your quarrying goals.

Shafttech is the no. 1 heavy industry expert in Southeast Asia.