Industry 4.0 and Factory Automation

Industry 4.0 represents the fourth revolution of industrialisation, where automation takes the front seat in enhancing factory processes, data and machine learning. Using the Industrial Internet of Things (IIoT), factories can adopt smart and autonomous systems that can collect data and communicate with equipment. These smart systems not only allow machines to make intelligent routing decisions without the need for operator intervention, they can also identify send feedback for problems that have occurred in the machines. By merging real and virtual worlds, companies can develop smarter production models to improve efficiency.

For the semiconductor industry, industry 4.0 offers manufacturers a fully decentralized operations model. With devices communicating with one another, the information gathered in this model will increase flexibility and productivity, as well as reduce costs in purchasing unnecessarily sophisticated parts.

How does Shafttech play a role in Factory Automation?

Further up the supply chain, Shafttech is one of the major component supplier for the Semiconductor industry. With our expertise in the automation, we are the driving force behind the companies that manufacture essential devices or Intel, Sandisk, Sony, Panasonic and Seagate.

In order to integrate with the cloud data and analytics of manufacturing, we offer full advanced motorized solutions that are used with with lasers, machine vision, dispensers that give precise positioning accuracy.

Application of our products in Semiconductor machines

Linear Actuators and Miniature actuators

In the semiconductor manufacturing, machines are used to place devices onto a printed circuit board (PCB). In between these devices, there is also a conveyor system to ferry the PCB to different stages. During this travel, each PCB goes through an inspection process to check if it is damaged or if there are any errors. Shafttech specialises in Linear Actuators and Miniature actuators for these high speed, precise pick and place operations, as well as for inspection.

GIF 1: Animation of linear actuators and miniature actuators used in conjunction in a semiconductor machine.

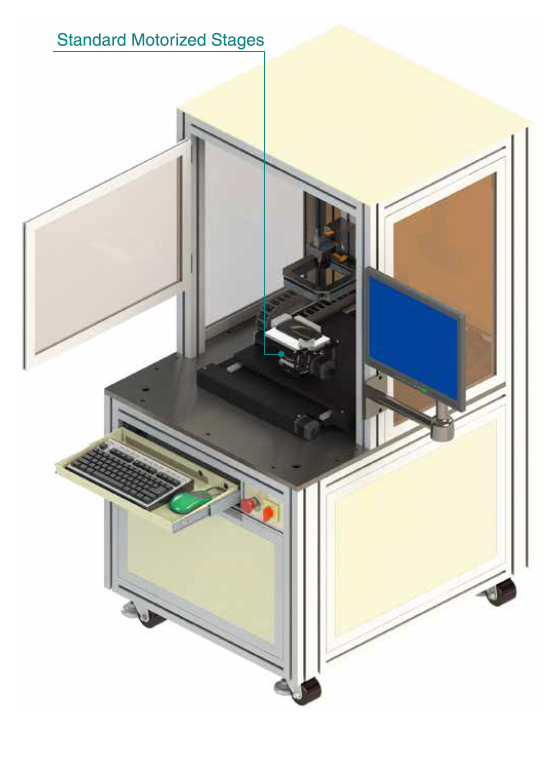

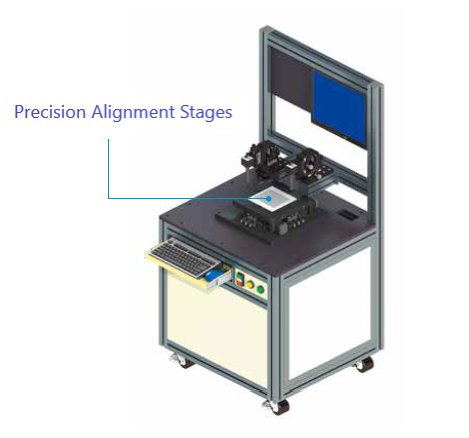

Motorised Positioning Stages and Alignment Stages

During the manufacturing of these high precision devices, many of these sensors require micron or sub-micron precision during assembly. For this, we can offer Motorised positioning stages of different types, to allow real-time multi-axis motion that synchronises with other devices.

Shafttech carries a wide range these Ball-screw driven Positioning stages and Precise Alignment stages to suit various application requirements.

Image 1: Collage of different Precision Motorized stages with single axis (X-axis) or multiple axis (XY, XYZ, XXY, XZ etc).

GIF 2: Animation of a precision manual stage and a precision alignment stage used in the Electric Vehicle (EV) manufacturing process.

GIF 3: Video of a Ball Screw-Driven XXY Alignment Motorised Stage with Motorised Positioners that can be used for precision scanning and PCB alignment testing.

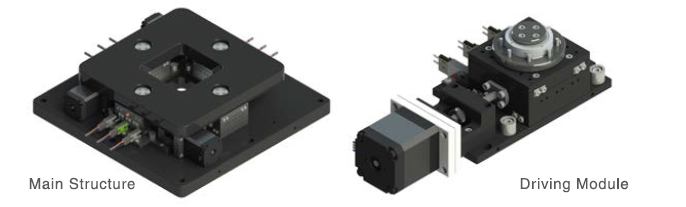

Image 2: [Left] Image of an Ball Screw-Driven XXY Alignment Motorised Stage and [Right] image of a Motorised Positioner as a driver.

Please contact us for more information on precision stages and XY tables. Download catalogues of these products in the links below:

For more info on Linear actuators, click here.

For more info on Miniature actuators, click here.

For more info on Motorised Positioning stages, click here.

For more info on Precision Alignment Stages, click here.

For more info on XY tables, click here.