One of the most common services that we do at Shafttech is gearbox overhaul. In this article, we will break down the gearbox overhaul process.

In the heart of any factory, gearboxes orchestrate the movement of machinery by transferring power from motor to equipment, ensuring production lines run efficiently. Without a well-functioning gearbox, even the most powerful motors cannot translate to productive output. But industrial gearboxes are susceptible to wear and tear over time. To maintain optimal performance and prevent costly downtime, a proactive approach to gearbox maintenance is crucial. This is where gearbox overhaul come in.

What is an Industrial Gearbox Overhaul?

An industrial gearbox overhaul is a planned, comprehensive service that involves the complete disassembly, cleaning, inspection, and repair or replacement of all gearbox components. Unlike minor repairs that focus on specific issues, an overhaul addresses the overall health of the gearbox, extending its lifespan and preventing unexpected breakdowns.

Benefits of a Gearbox Overhaul

Doing a gearbox overhaul allows you to extend the gearbox lifespan. By proactively replacing worn parts, you minimize the risk of sudden gearbox failures that can halt production lines. Catching and addressing problems early on also prevents more extensive (and expensive) repairs down the road, reducing maintenance costs.

A typical industrial gearbox overhaul follows these key steps:

Pre-Overhaul Inspection: Our technician will assess the gearbox’s overall health through vibration analysis, oil sampling, and a visual inspection. This helps determine the extent of the overhaul needed.

Gearbox Removal and Disassembly: The gearbox is carefully removed from the production line and disassembled in a clean environment. Each component is meticulously documented and tagged. We will then provide an investigation report on the condition of individual parts within the gearbox.

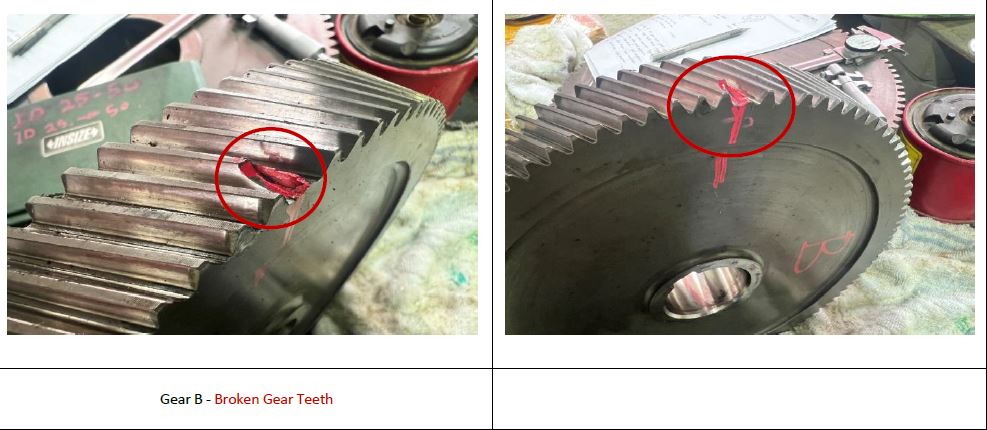

a. Check the gears

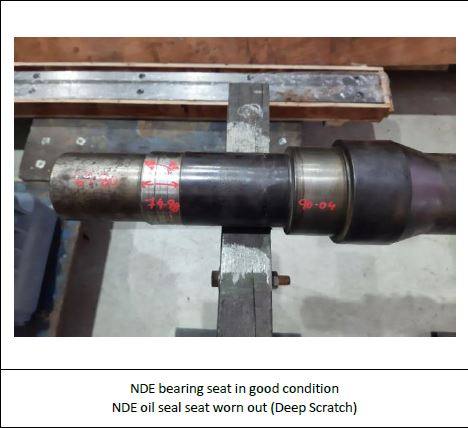

b. Check the Shaft for the bearing seat and oil seal seat

DE = Drive end. NDE = Non-drive end

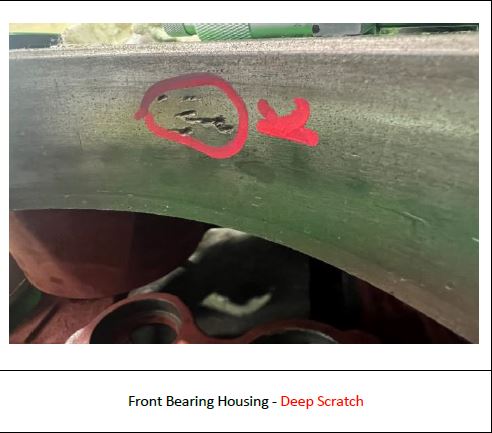

c. Check the bearings and bearing housings

d. Check oil seal housings

Repair or Replacement: Depending on the condition, parts may be repaired or replaced with high-quality components.

Reassembly and Testing: The gearbox is meticulously reassembled, ensuring proper alignment and torque specifications are met. The reassembled gearbox undergoes rigorous testing to confirm smooth operation and proper gear changes under load.

Gearbox Reinstallation and Commissioning: The overhauled gearbox is reinstalled on the production line, and final adjustments are made to ensure proper alignment with connected equipment.

Factors to Consider for Gearbox Overhaul Frequency

The recommended frequency for gearbox overhauls depends on several factors. One of them is the operating duration. Gearboxes operating for extended periods will require more frequent overhauls. Lead conditions also affect overhaul frequency as, gearboxes subjected to heavy loads will experience wear and tear faster.

Preventive measures like regular oil changes and proper lubrication practices can help to extend the lifespan between overhauls. Consulting with a qualified gearbox service provider can help you determine the optimal overhaul schedule for your specific equipment and operating conditions.

Conclusion

By incorporating gearbox overhauls into your preventative maintenance plan, you can ensure your factory operates at peak efficiency. Reduced downtime, enhanced reliability, and extended gearbox life all contribute to a more productive and cost-effective manufacturing environment.

Reliable Gearbox Overhauls, Every Time – Contact Shafttech for a reliable and detailed inspection of your gearbox.