Linear guides are often used in a two-rail system, where rail parallelism plays an important part in ensuring accuracy.

When the rails are not installed with proper alignment, it will severely affect the performance of the linear guide speed, and in serious cases, cause friction and damage the linear guide assembly.

Nowadays you can find linear guides that come equipped with parallelism accuracy. STAF linear guides offers standard linear guide systems with proper parallelism. They are manufactured to ensure equal tolerances on both sides of the assembly, ensuring precise parallelism to the micron level. If you need any of these, feel free to contact us.

Many often overlook the importance of preload when choosing suitable linear guides for their application. Preload, otherwise known as “clearance”, is the elimination of internal distance between the rail and the carriage. Having a preload for your linear guides helps to increase rigidity and reduce deflection.

Having a preload or high preload is not necessarily good because more force is needed to move the block along the rail. If your application requires positional accuracy, a light preload is good enough. Anything more than this will make the block unnecessarily rigid and harder to move. However, for cases like picking robots where heavy loads are applied far away from the linear blocks, a heavy preload is needed to accommodate displacement.

For linear motion applications, one of the most important checks during a regular maintenance is ensuring sufficient lubrication. Insufficient lubrication in linear guide systems causes increased friction, and overtime it could result in scratching or pitting on linear rails.

One easy way to check for this is to swipe the linear rail with your finger. There should be a thin layer of grease or oil on it. If it is too dry or dripping wet with lubricant, it is a sign that some adjustments need to be made. It is also important that you use the grease recommended by the manufacturer. Lubricants with higher viscosity can have better protection against contaminants, however, it could also cause congestion in the raceways of the linear blocks. The speed, temperature and environment of your application can all affect the performance of lubricant.

If you find your grease leaking out of your linear block during maintenance, the method of re-greasing could be incorrect. The right way is to alternate the pumping of grease and sliding of block along the rail to ensure the grease is distributed evenly into the raceways. You can find the accurate way of pumping grease into your linear block here.

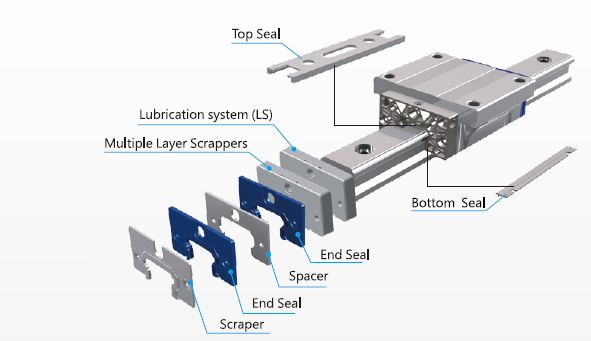

If you are unable to pump grease manually, you could also opt for automatic lubricators or self-lubricating linear guides. Shafttech offers self-lubricating linear guides, which contains a Lubrication system (LS) attached to the end of your linear block. You can replace this external cartridge easily.

As we know, there are numerous linear guides brands in the market, and they are often “interchangeable” in terms of dimensions. However, linear guide systems are manufactured differently for different brands. The general rule of thumb when you are finding a replacement is that the linear guide block and rail has to come from the same manufacturer. Even if the dimensions appear to be the same, the design of the raceway and internal structure of the linear block are not meant to fit the rail from another manufacturer. A mismatch in block and rail brand can damage the components over time.

We also have to be aware of the type of block purchased from the same manufacturer during replacement. A caged type linear block has a retainer to hold the steel balls in place, reducing noise and friction within the block. In most brands, the caged type block has to be paired with a specific matching rail.

Fortunately, there are ways around it. STAF linear guides are designed in a way to allow caged and non-caged blocks to be used on the same rail, assuming all else the same. This makes it a whole lot easier for replacement.

Similarly, the accuracy of block and rail has to the same. It is generally recommended to purchase a full set of block and rail for replacement if your application requires high or precision grade. This is because due to wear and tear over time, the tolerances on your linear rail may no longer meet the requirement of the precision grade required.