Introduction:

Ball screws play a crucial role in many automation systems, offering high precision and efficiency in linear motion systems. Choosing the correct ball screw size is essential for ensuring optimal performance and longevity of your machinery. In this article, we will guide you through the process of measuring and selecting the right ball screw size. We will also highlight the brand, STAF, as a trusted provider of high-quality ball screws.

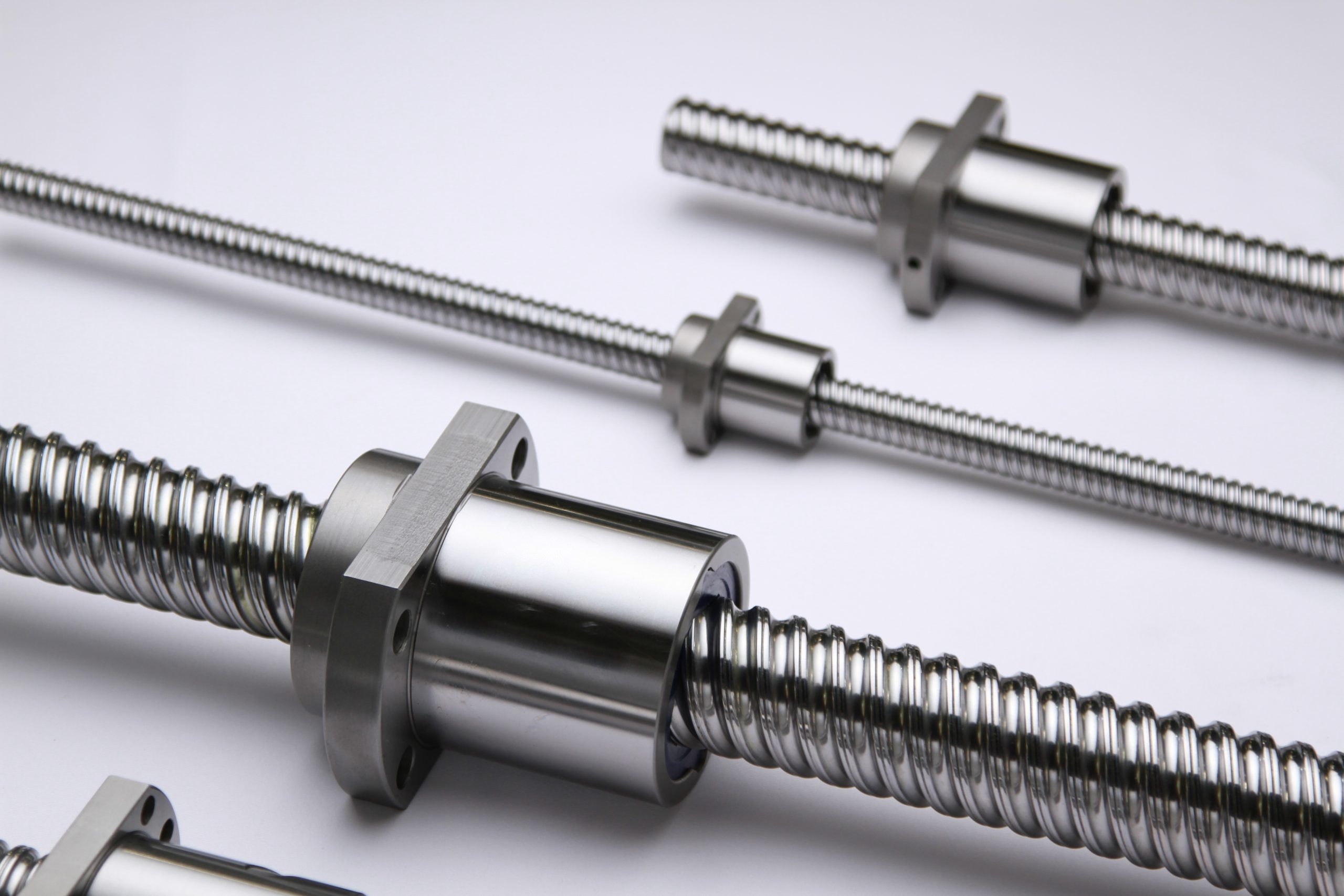

Image 1: A picture showing how to measure ball screw lead

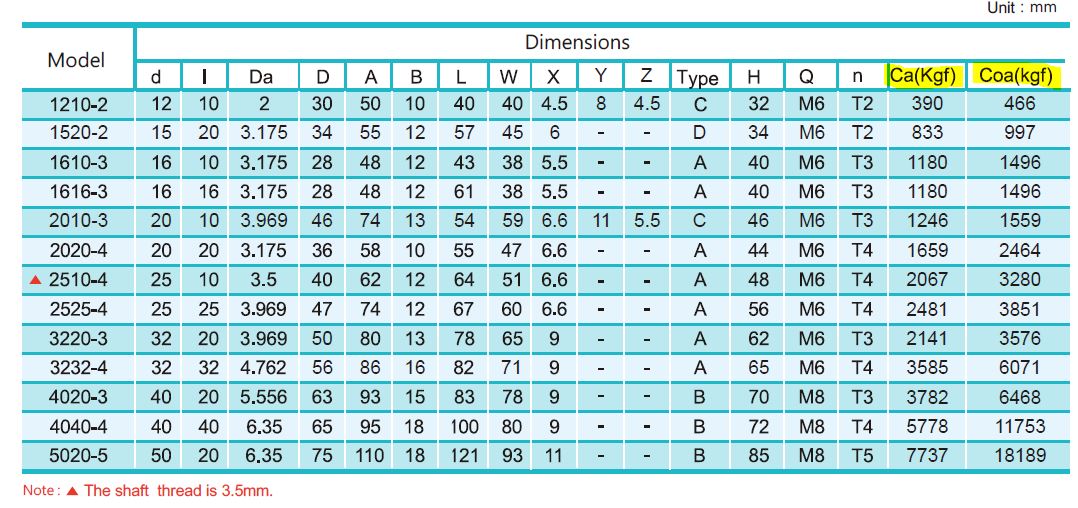

Image 2: Ball screw table from STAF catalogue highlighting the basic load ratings columns for Ball screw type FSC.

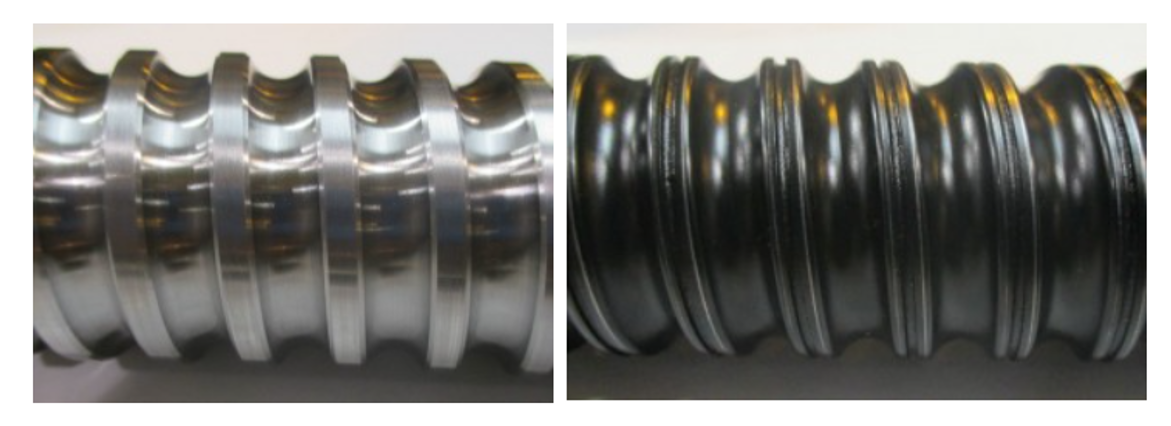

Image 3: [LEFT] Ground Ball screw. [RIGHT] Rolled Ball Screw

Awarding-winning, high quality ball screws from STAF (Taiwan)

When it comes to selecting a reliable ball screw brand, STAF stands out as a trusted provider of high-quality products in Asia. STAF offers a wide range of ball screw options, including precision-ground and rolled ball screws, to meet diverse industrial needs. They are known in Taiwan as the No.1 in linear motion technology.

STAF ball screws incorporate self-developed nanotechnology and stringent quality control processes to ensuring consistent performance and reliability. Their products are designed to deliver long-lasting, smooth and precise linear motion, resulting in improved machine performance and reduced maintenance. In 2023, STAF has just opened a brand new bigger IoT facility in Daxi to cater to the growing demand.

STAF and Shafttech

Due to Shafttech’s large presence in Southeast Asia (SEA), we were awarded SEA distributorship by STAF in 2015. Since then, this partnership has provided comprehensive technical support and application engineering expertise to assist customers in selecting the right ball screw size for their specific requirements. With the support of our customers globally, Singapore and Malaysia has become a hub for STAF in terms of stock inventory. This dedication to customer satisfaction sets STAF apart as a reliable partner in the field of linear motion systems.

Conclusion:

Selecting the correct ball screw size is crucial for achieving optimal performance and longevity in your linear motion system. By understanding the parameters involved, considering load capacity, speed requirements, and precision levels, you can make an informed decision. It is also important to purchase from reputable brands like STAF, which offer high-quality ball screws and expert support. With the right ball screw size, you can ensure smooth, precise, and efficient linear motion in your applications.

(Note: This article is for general applications. It is important to consult manufacturers’ guidelines and technical specifications when selecting ball screws for specific applications.)

If you want to know how to find a suitable replacement for an existing ball screw, check out this video!