Linear guides, also known as linear rails, are essential components in a wide range of industrial applications, providing smooth and precise linear motion. Choosing the right linear guide is crucial to ensure optimal performance, longevity, and cost-effectiveness. In this article, we will guide you through the process of selecting the right linear guide for your application, considering key factors such as load capacity, accuracy, environment, and maintenance requirements.

Load Capacity:

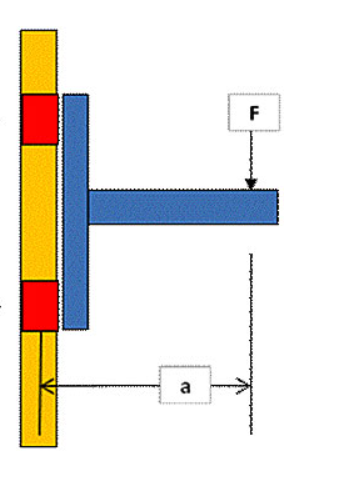

Determine the maximum load that the linear guide will need to support. Consider both static and dynamic loads, as well as any additional forces or moments acting on the system. It is also important to consider if the rail guides are used in a horizontal or a vertical application. Typically, the vertical application will require three times more load than a horizontal application. In the image below, you can see a common setup of a palletiser which has both X-axis and Y-axis linear guides. For Y-axis, you have to consider the distance to the load (a) and also the weight of the load itself (F). This will help you choose a linear guide with the appropriate load capacity and ensure stable and reliable operation.

Number of blocks per rail:

The number of blocks per rail and the distance between each block per rail depends on the surface area of the steel plate or object mounted on the block(s). Some linear guide blocks consist of 2, 4 or more mounting holes, and some blocks are wider than others. If two blocks are required per rail, it is best to use the widest possible distance between two blocks to operate in the more stable fashion.

Image: Different types of STAF linear guide blocks, including short and long blocks, blocks with two or four mounting hole, and blocks with a wider flange.

Accuracy and Precision:

Evaluate the required level of precision and repeatability for your application. Some applications, such as CNC machines or optical systems, demand high accuracy, while others may have more lenient requirements. Consider factors like positioning tolerance, backlash, and smoothness of motion. For Shafttech, we offer varying levels of precision for linear guides, as well as the option of having linear guide parallelism when two sets of linear guides are used in a parallel system with little to no misalignment.

Speed and Acceleration: Define the desired travel speed and acceleration for your application. Higher speeds and accelerations may require linear guides with specialized features, such as low friction or enhanced lubrication systems, to minimize heat generation and wear.

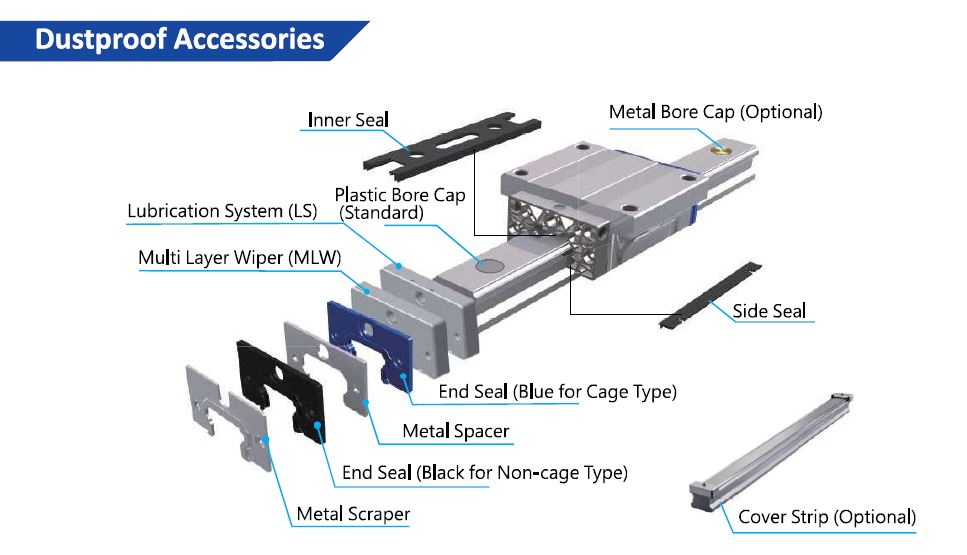

Environment and Conditions: Assess the operating environment of your application. Consider factors such as temperature extremes, humidity, dust, or corrosive substances. These conditions may dictate the choice of materials, sealing options, and protective coatings for the linear guide. Shafttech offers many grades of seal for linear guides. The standard linear guide comes with end seal and side seal. We will also be able to reinforce your current linear guides with more seals if needed, including scrappers that keep out dust in large amounts.

Maintenance and Cost Factors:

When selecting a linear guide, it’s crucial to consider the maintenance requirements and associated costs. Some factors to consider include:

Lubrication:- Determine the lubrication requirements of the linear guide. Some guides require regular lubrication, while others feature self-lubricating properties or maintenance-free options. The ease of lubrication is also important. In cases where the linear guides are highly inaccessible or downtime has to be reduced, we will recommend a auto-lubrication system that acts as a “juice pack” for the linear guide to run for long periods of time. Watch this video to learn more about our auto-lubrication system.

Service Life:- Evaluate the expected service life of the linear guide. Consider factors such as load capacity, operating conditions, and manufacturer specifications. Choosing a caged linear guide (BGC) can reduce vibration and prolong longer service life.

Conclusion: Selecting the right linear guide is essential to ensure optimal performance, accuracy, and longevity in your linear motion system. By considering factors such as load capacity, accuracy, speed, environmental conditions, and maintenance requirements, you can make an informed decision. Check in with Shafttech now for recommendations on linear guide selection or conversion as we have a team of experienced engineers who can assist you any time.